Have you ever struggled to understand positive displacement pump curves? In this blog post, we’ll break down the essential components of a pump curve and explain how to interpret the data.

By the end of this article, you’ll be able to confidently read and analyze pump curves, empowering you to make informed decisions when selecting and operating positive displacement pumps.

What Is a Positive Displacement Pump Curve

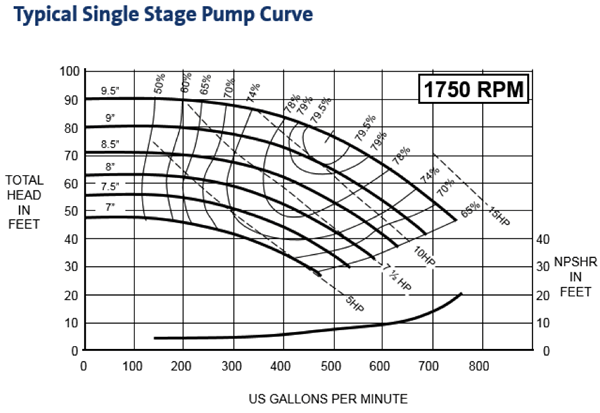

A positive displacement pump curve is a graphical representation of a pump’s performance, showing the relationship between flow rate, pressure, and other variables.

Capacity/Flow Rate

Capacity, also known as flow rate, is a crucial parameter in positive displacement pump curves. It represents the volume of fluid the pump can deliver per unit of time, typically expressed in gallons per minute (GPM) or cubic meters per hour (m³/h).

The flow rate is determined by the pump’s displacement per revolution and its operating speed. It is important to note that the actual flow rate may be slightly lower than the theoretical value due to factors such as slip and volumetric efficiency.

Pump Slip

Pump slip refers to the difference between the theoretical flow rate and the actual flow rate of a positive displacement pump. It occurs due to internal leakage within the pump, such as fluid passing between the pumping elements and the casing or through clearances.

Slip is expressed as a percentage of the theoretical flow rate and can vary depending on factors such as fluid viscosity, pressure, and pump wear.

Viscosity

Viscosity is a measure of a fluid’s resistance to flow. In positive displacement pump curves, viscosity is an important consideration as it affects the pump’s performance and efficiency. Higher viscosity fluids require more power to pump and can reduce the pump’s flow rate due to increased friction and slip. Pump curves often include information on the acceptable viscosity range for optimal performance.

Differential Pressure

Differential pressure, also known as the pressure rise or head, is the difference between the pump’s discharge pressure and suction pressure. It represents the amount of pressure the pump must overcome to move the fluid from the suction side to the discharge side.

Positive displacement pump curves typically show the relationship between flow rate and differential pressure. As the differential pressure increases, the flow rate may decrease due to increased slip and reduced volumetric efficiency.

Brake Horsepower (BHP)

Brake horsepower (BHP) is the actual power required to drive the pump shaft and is a key parameter in positive displacement pump curves. It takes into account the power losses due to mechanical inefficiencies, such as friction in bearings and seals.

BHP is typically plotted against flow rate or differential pressure on the pump curve. As the flow rate or differential pressure increases, the BHP required to maintain the pump’s operation also increases.

Net Positive Suction Head Required (NPSHr)

Net Positive Suction Head Required (NPSHr) is the minimum pressure required at the pump inlet to prevent cavitation. Cavitation occurs when the fluid’s vapor pressure is higher than the local pressure, causing vapor bubbles to form and collapse, leading to reduced performance and potential damage to the pump.

Positive displacement pump curves often include NPSHr information, which helps in determining the necessary suction conditions for proper pump operation.

Pump Speed

Pump speed, typically expressed in revolutions per minute (RPM), is another important parameter in positive displacement pump curves. The pump speed directly affects the flow rate, with higher speeds resulting in higher flow rates. However, increasing the pump speed also increases the power consumption and may impact the pump’s efficiency and longevity.

Pump curves may include information on the allowable speed range for the pump, considering factors such as fluid properties, system requirements, and pump design limitations.

FAQs

What information can be found on a positive displacement pump curve?

A positive displacement pump curve typically includes flow rate, discharge pressure, pump speed, power consumption, and efficiency.

How do I determine the flow rate from a pump curve?

To determine the flow rate, locate the point on the curve where the desired discharge pressure intersects the curve, then read the corresponding flow rate value on the x-axis.

How do I determine the maximum pressure a pump can generate?

The maximum pressure a pump can generate is found at the point where the flow rate is zero, also known as the “shutoff head” or “dead head.”

What is the difference between a single-speed and variable-speed pump curve?

A single-speed pump curve shows the performance at one specific speed, while a variable-speed pump curve displays multiple curves, each representing a different speed.

In conclusion

Understanding how to read a positive displacement pump curve is crucial for selecting and operating pumps efficiently. By following these steps, you can make informed decisions and optimize your pumping system.

For more information on pump curves and pump selection, visit our website or contact our experts today.