Are you struggling to choose between pusher seals and non-pusher seals for your machinery? Understanding the differences can save you time, money, and headaches.

In this blog post, we’ll break down the key features, benefits, and drawbacks of each type. By the end, you’ll have the knowledge you need to make an informed decision.

What is Pusher Seals

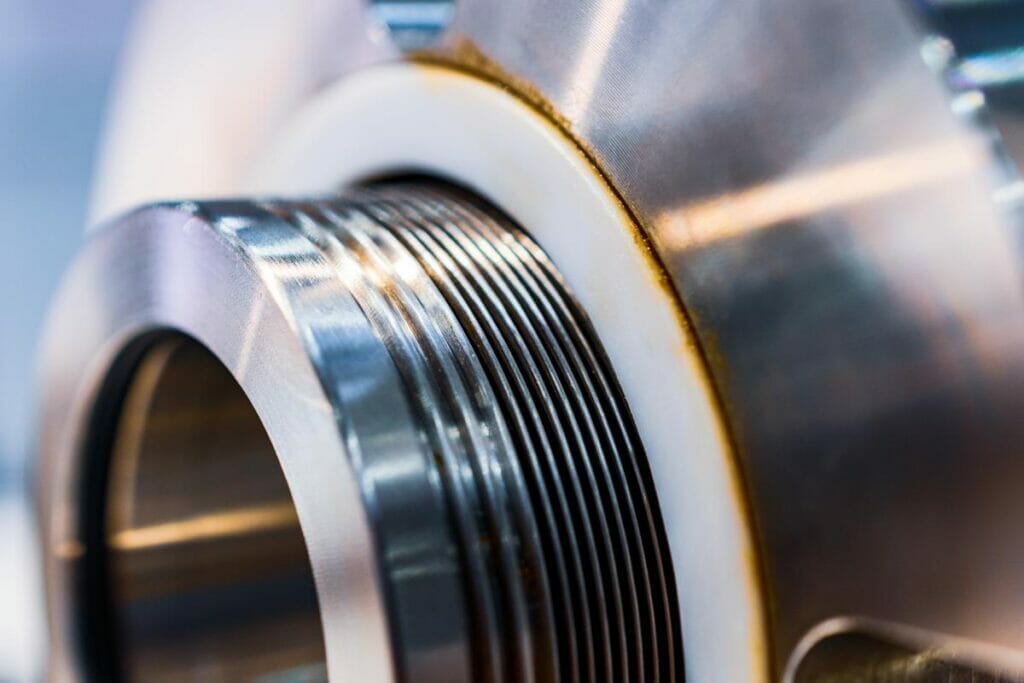

Pusher seals, also known as pusher-type mechanical seals, are a specific type of mechanical seal designed to provide a reliable sealing solution in rotating equipment. These seals consist of a stationary component (stator) and a rotating component (rotor) that work together to prevent leakage and contain the process fluid within the equipment.

In a pusher seal, the sealing faces are maintained in contact by a combination of hydraulic pressure and spring force. The springs, typically located behind the stationary sealing face, push the stator against the rotor to maintain a tight seal. This constant pressure ensures that the sealing faces remain in close contact, even under varying operating conditions.

Advantages of Pusher Seals

Pusher seals offer several advantages that make them a popular choice for various industrial applications:

- Simplicity: Pusher seals have a relatively simple design compared to other types of mechanical seals. This simplicity makes them easier to install, maintain, and repair, reducing downtime and maintenance costs.

- Versatility: Pusher seals can handle a wide range of process fluids, pressures, and temperatures, making them suitable for diverse industrial applications. They can be customized with different materials and configurations to meet specific application requirements.

- Reliability: The constant contact between the sealing faces, maintained by the spring force and hydraulic pressure, ensures a reliable seal even under challenging operating conditions. This reliability helps prevent leakage and enhances the overall safety of the equipment.

- Cost-effectiveness: Due to their simple design and ease of maintenance, pusher seals are generally more cost-effective than other types of mechanical seals. They offer a reliable sealing solution without the need for complex and expensive components.

Disadvantages of Pusher Seals

Despite their advantages, pusher seals also have some limitations:

- Limited speed capability: Pusher seals may not be suitable for high-speed applications, as the constant contact between the sealing faces can generate excessive heat and wear at high rotational speeds. This limitation can lead to premature seal failure and increased maintenance requirements.

- Sensitivity to misalignment: Pusher seals are more sensitive to misalignment compared to other types of mechanical seals. Any misalignment between the rotating and stationary components can cause uneven wear on the sealing faces, leading to leakage and reduced seal life.

- Higher leakage rates: Due to the constant contact between the sealing faces, pusher seals may exhibit higher leakage rates compared to non-pusher seals. While the leakage is still within acceptable limits for most applications, it may not be suitable for processes that require extremely low leakage rates.

- Limited dry running capability: Pusher seals rely on the process fluid for lubrication and cooling. In applications where the process fluid is absent or intermittent, such as during startup or shutdown, the lack of lubrication can cause damage to the sealing faces and lead to premature failure.

What is Non-Pusher Seals

Non-pusher seals, also known as non-pusher mechanical seals, are a type of mechanical seal that does not rely on a spring to maintain contact between the sealing faces. Instead, these seals utilize hydraulic pressure or magnetic force to keep the sealing faces in close contact, preventing leakage.

Non-pusher seals are designed to overcome the limitations of traditional pusher seals, which can experience issues such as hang-up, distortion, and uneven wear. By eliminating the need for a spring, non-pusher seals offer improved performance and reliability in various applications.

Advantages of Non-Pusher Seals

Non-pusher seals offer several advantages over traditional pusher seals:

- Enhanced reliability: The absence of a spring eliminates the risk of spring failure, ensuring more consistent and reliable sealing performance.

- Reduced friction: Non-pusher seals generally have lower friction between the sealing faces, which can lead to increased efficiency and reduced heat generation.

- Improved chemical compatibility: The materials used in non-pusher seals can be selected to better withstand aggressive chemicals and extreme temperatures.

- Longer seal life: The even wear and reduced distortion of non-pusher seals can result in extended seal life, reducing maintenance costs and downtime.

- Compact design: Non-pusher seals often have a more compact design compared to pusher seals, making them suitable for applications with limited space.

Disadvantages of Non-Pusher Seals

Despite their numerous advantages, non-pusher seals also have some disadvantages:

- Higher initial cost: Non-pusher seals are generally more expensive than traditional pusher seals due to their advanced design and materials.

- Limited axial movement: Non-pusher seals have limited ability to accommodate axial shaft movement, which can be problematic in applications with significant shaft movement or misalignment.

- Sensitivity to pressure fluctuations: Some non-pusher seals may be more sensitive to pressure fluctuations, which can affect their sealing performance.

- Specialized installation: Installing non-pusher seals may require specialized tools and training, which can increase installation costs and complexity.

- Potential for face separation: In some cases, the absence of a spring can lead to face separation under certain operating conditions, compromising the seal’s performance.

The Difference Between Pusher Seals and Non-Pusher Seals

Pusher seals and non-pusher seals are two distinct types of mechanical seals used in various industrial applications. The primary difference lies in their design and how they handle the thermal expansion of the seal components.

Pusher seals, also known as conventional seals, feature a design that allows the seal faces to move axially. The springs in a pusher seal are located behind the rotating seal face, pushing it against the stationary face. This design accommodates thermal expansion and contraction of the seal components, ensuring consistent contact between the seal faces.

On the other hand, non-pusher seals, also referred to as bellows seals, have the springs located outside the fluid being sealed. The bellows assembly is welded to the rotating seal face, eliminating the need for dynamic O-rings. As the seal faces expand due to temperature changes, the bellows compress or expand accordingly, maintaining a constant closing force between the seal faces.

Factors to Consider When Selecting Between Pusher and Non-Pusher Seals

When choosing between pusher and non-pusher seals, several factors should be taken into account to ensure optimal performance and reliability.

Temperature Range

Non-pusher seals are generally preferred for high-temperature applications, as they can accommodate greater thermal expansion without compromising seal face contact. Pusher seals may be more suitable for moderate temperature ranges.

Pressure Capabilities

Non-pusher seals typically have higher pressure ratings compared to pusher seals, making them a better choice for high-pressure applications. Pusher seals may be sufficient for low to moderate pressure environments.

Fluid Compatibility

Both pusher and non-pusher seals can be constructed from a variety of materials, including carbon, silicon carbide, and tungsten carbide. The selected material should be able to withstand the chemical properties and corrosiveness of the fluid to prevent premature seal failure.

Shaft Speed and Runout

Non-pusher seals are generally more tolerant of high shaft speeds and runout due to their design, which allows for better dynamic tracking of the seal faces. Pusher seals may be more susceptible to face separation and leakage under these conditions.

Cost and Maintenance

Pusher seals are typically less expensive than non-pusher seals due to their simpler design and more readily available components. However, non-pusher seals may offer longer service life and reduced maintenance requirements, potentially offsetting the initial cost difference over time.

FAQs

Which type of mechanical seal is more commonly used?

Pusher seals are more common due to their simpler design and lower cost compared to non-pusher seals.

In what applications are non-pusher seals typically used?

Non-pusher seals are used in high-pressure, high-temperature, and high-speed applications where pusher seals may not be suitable.

Which type of mechanical seal is more cost-effective?

Pusher seals are generally more cost-effective due to their simpler design and lower manufacturing costs compared to non-pusher seals.

Can a pusher seal be replaced with a non-pusher seal?

In most cases, a pusher seal cannot be directly replaced with a non-pusher seal without modifications to the equipment due to differences in design and installation requirements.

In Conclusion

In summary, both pusher and non-pusher seals offer distinct advantages depending on the application requirements.

For more detailed guidance on selecting the right seal for your needs, contact our experts today. Stay informed by subscribing to our newsletter for the latest updates and insights.