Choosing between single and double mechanical seals depends on the specific operational demands and safety requirements. Single mechanical seals offer ease of installation and cost advantages, while double mechanical

In this blog post, we will break down the key distinctions between single and double mechanical seals.

By the end of the article, you’ll have a clear understanding of which seal type best suits your needs.

What is Single Mechanical Seal

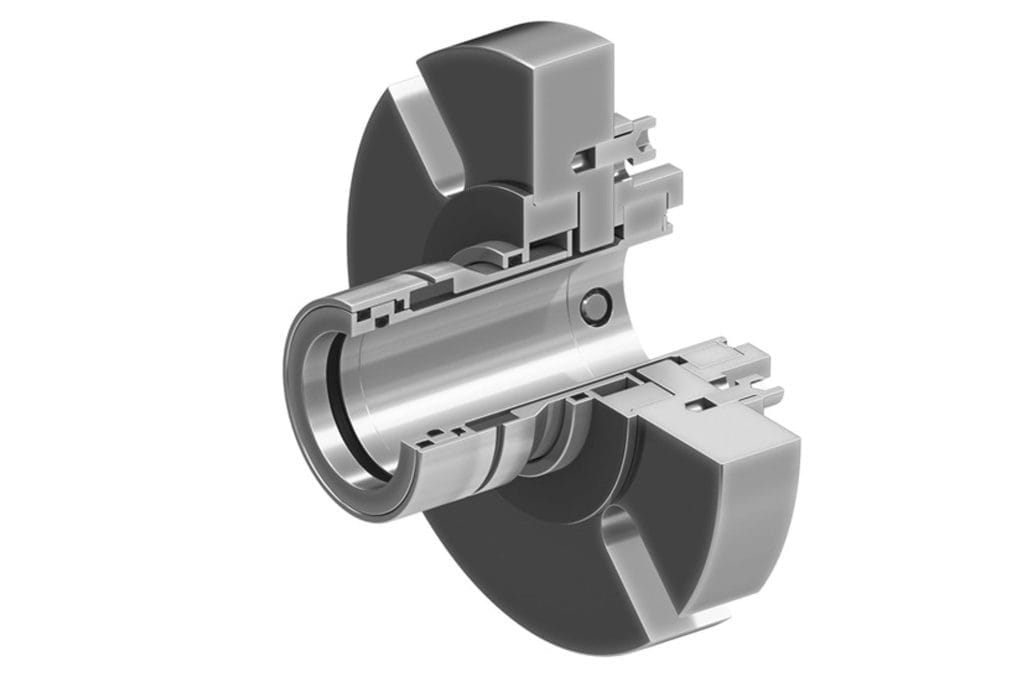

A single mechanical seal is a device used to prevent fluid leakage in pumps and rotating equipment. It consists of two flat surfaces, one stationary and one rotating, which are pressed together by a spring. These surfaces are often made from materials like carbon, ceramic, or silicon carbide.

The primary seal is formed between the rotating seal face and the stationary seal face. This seal prevents the process fluid from leaking out along the pump shaft. The secondary seal, often an o-ring or gasket, provides a backup to the primary seal in case of failure.

What is Double Mechanical Seal

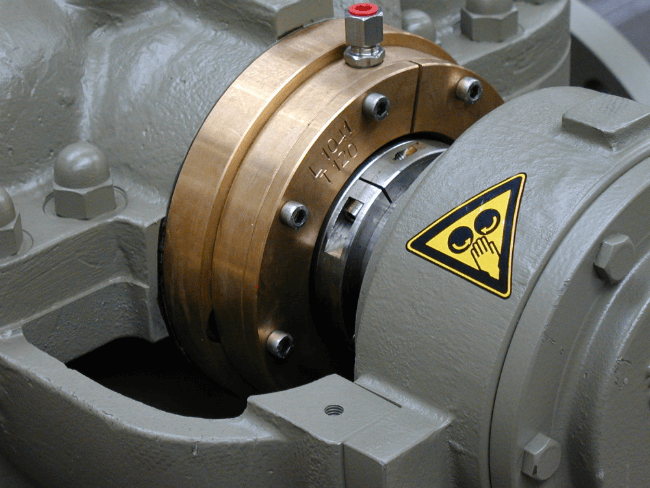

A double mechanical seal consists of two sets of mechanical seals installed in a series. These seals provide an additional level of protection against leaks, making them ideal for handling hazardous fluids and maintaining environmental regulations.

The primary seal is the first line of defense, located closest to the process fluid. The secondary seal, also known as the outboard seal, provides backup protection in case of primary seal failure.

Double seals often use a barrier fluid between the two sets of seals. This barrier fluid acts as a lubricant and coolant, reducing frictional heat and preventing dry running. The barrier fluid can be a clean fluid, flush liquid, or buffer fluid.

Types of Double Mechanical Seals

Back to Back Double Mechanical Seal

A Back to Back Double Mechanical Seal consists of two seals arranged in opposite directions. The primary seal faces the process fluid, while the secondary seal faces the barrier fluid. This arrangement provides robust sealing solutions for high-pressure applications.

Barrier fluids are introduced between the seals to prevent process fluid leakage. The barrier fluid pressure is usually higher than the process fluid pressure. This ensures that the process fluid does not leak past the primary seal. This type of seal arrangement is common in the chemical industry and for handling hazardous fluids.

Face to Face Double Mechanical Seals

Face to Face Double Mechanical Seals have two seal faces positioned against each other. This configuration allows for a compact design. The barrier fluid is supplied between the two seal faces. This helps to cool and lubricate the seals.

Face to Face seals are ideal for applications with moderate pressure conditions. They are often used in centrifugal pumps and other rotating equipment. This type of seal is effective in preventing fluid leaks and protecting against product leakage.

Tandem Double Mechanical Seals

Tandem Double Mechanical Seals consist of two seals arranged in series. The primary seal faces the process fluid, and the secondary seal faces the atmosphere. The barrier fluid is introduced between the two seals to provide additional protection.

This type of seal arrangement is useful for handling toxic fluids and hazardous products. Tandem seals offer a high level of safety and protection against leaks. They are commonly used in the food industry and for applications requiring clean fluid.

The Difference Between Single and Double Mechanical Seals

Single mechanical seals and double mechanical seals serve the same primary purpose: to prevent fluid leakage in pumps and other rotating equipment. However, their designs and functionalities differ significantly.

Single mechanical seals have one set of sealing faces, while double mechanical seals have two sets of sealing faces, providing an additional layer of protection against leakage.

Protection Level

- Single seals offer basic protection against leaks.

- Double seals provide an additional level of protection, making them suitable for hazardous fluids and high-pressure conditions.

Barrier Fluids

- Single seals do not require barrier fluids.

- Double seals use barrier fluids or buffer fluids to maintain pressure and prevent leakage.

Installation and Maintenance

- Single seals are easier to install and maintain.

- Double seals are more complex and may require qualified engineers for installation and maintenance.

Cost

- Single seals are generally more cost-effective.

- Double seals have a higher initial cost but offer long-term benefits in terms of safety and reliability.

Applications

- Single seals are suitable for a wide range of applications, including clean fluids and non-hazardous environments.

- Double seals are ideal for challenging conditions, including toxic fluids, abrasive fluids, and high-pressure applications.

Can a single mechanical seal be upgraded to a double mechanical seal

In some cases, it is possible to upgrade a single mechanical seal to a double mechanical seal. However, this depends on factors such as the pump design, available space, and the compatibility of the existing seal components with the double seal arrangement.

In Conclusion

In summary, single mechanical seals are simpler and cost-effective, while double mechanical seals offer enhanced reliability and safety.

For expert advice on choosing the right seal for your application, contact our team today. Explore our comprehensive range of mechanical seals to find the perfect fit for your needs.