Have you ever wondered about the different types of centrifugal pumps? These essential machines are used in various industries to move liquids efficiently.

In this blog post, we’ll explore the main types of centrifugal pumps, their unique features, and their specific applications. By the end, you’ll have a clear understanding of which pump best suits your needs.

Radial Flow Pumps

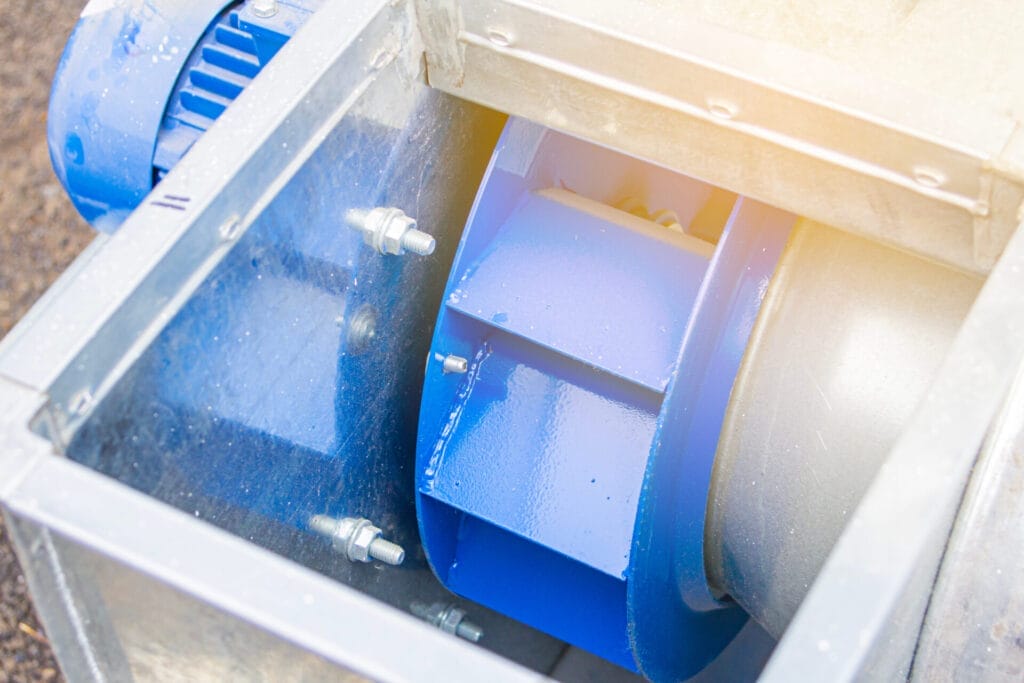

Radial flow pumps are a type of centrifugal pump that moves fluid by using the centrifugal force generated by the rotation of an impeller. The fluid enters the pump near the center of the impeller and is accelerated outward by the impeller vanes before being discharged at the outer edge of the impeller.

Single Stage

Single stage radial flow pumps have a single impeller that is used to generate the centrifugal force necessary to move the fluid. These pumps are typically used for lower pressure and flow rate applications, such as water supply, irrigation, and general industrial use.

Multistage

Multistage radial flow pumps have two or more impellers arranged in series, with each impeller increasing the pressure of the fluid as it passes through the pump. These pumps are used for higher pressure and flow rate applications, such as boiler feed, high-pressure water supply, and oil and gas production.

The number of stages in a multistage radial flow pump depends on the specific application and the required pressure and flow rate. Each stage adds to the overall pressure of the fluid, allowing the pump to achieve higher discharge pressures than single stage pumps.

Axial Flow Pumps

Axial flow pumps are a type of centrifugal pump designed to move fluid along the axis of the impeller. These pumps are characterized by their ability to handle high flow rates while operating at lower pressures compared to other centrifugal pump types.

The impeller of an axial flow pump consists of a series of blades arranged in a propeller-like configuration. As the impeller rotates, it imparts kinetic energy to the fluid, causing it to flow in a direction parallel to the pump’s shaft.

Propeller Pumps

Propeller pumps are a specific type of axial flow pump that closely resemble boat propellers in their design. These pumps feature a set of blades mounted on a rotating hub, which is driven by the pump’s motor.

As the propeller rotates, it creates a low-pressure area behind the blades, drawing the fluid into the pump. The fluid is then pushed forward by the propeller’s motion, creating a continuous flow.

Propeller pumps are well-suited for applications that require high flow rates and low head pressures, such as drainage systems, circulation systems, and cooling water intakes.

Mixed Flow Pumps

Mixed flow pumps are a hybrid design that combines features of both axial flow and radial flow centrifugal pumps. In these pumps, the impeller is designed to direct the fluid both axially and radially as it passes through the pump.

The impeller of a mixed flow pump typically has a conical shape, with the fluid entering axially at the smaller end and gradually transitioning to a radial flow as it moves towards the larger end.

Mixed flow pumps offer a balance between the high flow rates of axial flow pumps and the higher head pressures generated by radial flow pumps. They are commonly used in applications such as water supply systems, sewage treatment plants, and industrial process pumping.

Peripheral Pumps

Peripheral pumps are a type of centrifugal pump that operate at lower flow rates and higher heads compared to other centrifugal pump designs. They are characterized by their unique impeller design, which features a large number of small vanes arranged around the periphery of the impeller.

Peripheral pumps are well-suited for applications that require high pressure and low flow rates, such as boiler feed, reverse osmosis, and high-pressure cleaning. They are also known for their ability to handle liquids with entrained gases or vapors.

Regenerative Turbine Pumps

Regenerative turbine pumps, also known as regenerative flow or side channel pumps, are a specific type of peripheral pump. They feature an impeller with a series of small cells or buckets that rotate in a circular housing, creating a regenerative flow pattern.

As the fluid enters the pump, it is accelerated by the impeller and flows through the cells, gaining energy with each pass. This regenerative action allows the pump to generate high pressures at relatively low flow rates, making them ideal for applications such as boiler feed, pressure boosting, and small-scale industrial processes.

Vortex Pumps

Vortex pumps, also known as recessed impeller pumps, are another type of peripheral pump designed to handle liquids with high concentrations of solids or stringy materials. They feature an impeller that is recessed into the pump casing, creating a vortex flow pattern that minimizes contact between the impeller and the pumped fluid.

This unique design allows vortex pumps to handle liquids with large solids, such as sewage, sludge, and industrial wastewater, without clogging or damaging the impeller. The recessed impeller also reduces wear and extends the pump’s service life, even when handling abrasive or corrosive fluids.

Specialty Centrifugal Pumps

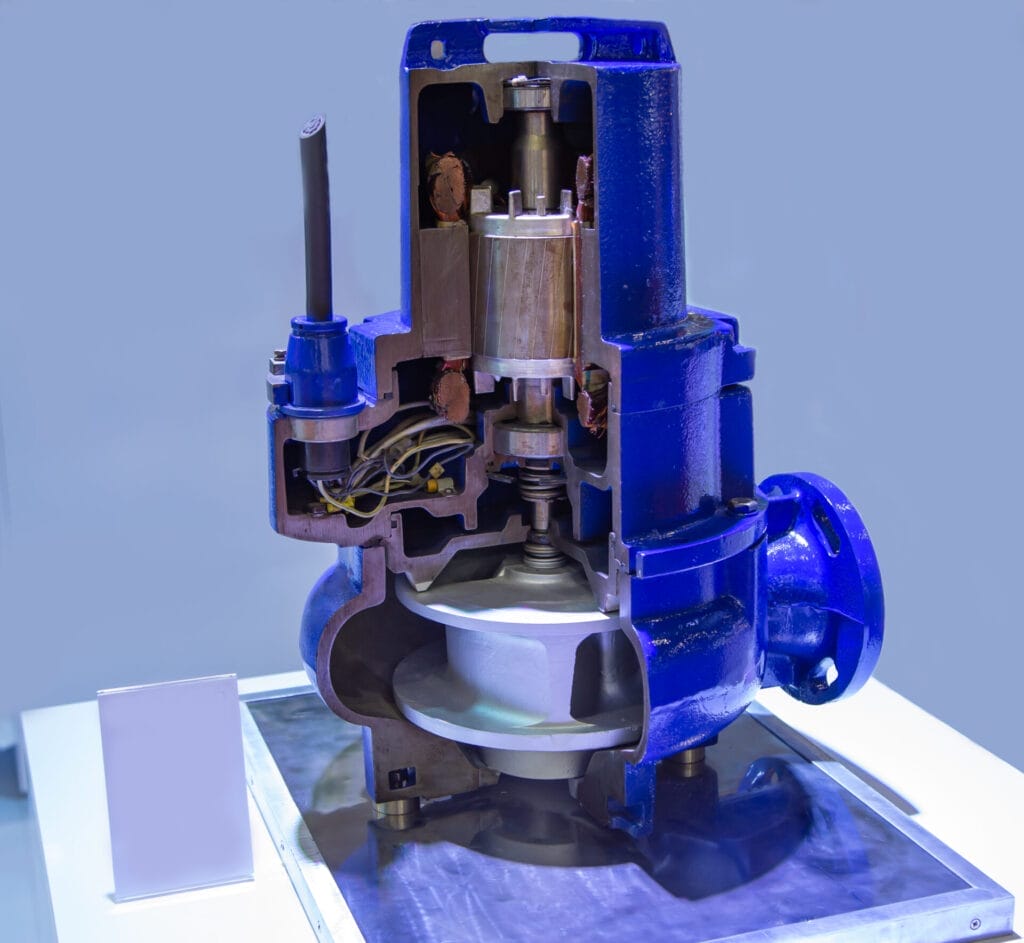

Submersible Pumps

Submersible pumps are designed to operate while fully submerged in the pumped liquid. They are commonly used in applications such as water wells, sewage treatment plants, and offshore oil production. The motor and pump are integrated into a single unit, which is sealed to prevent liquid from entering the motor. Submersible pumps are efficient and reliable, as they eliminate the need for long drive shafts and external motors.

Sump Pumps

Sump pumps are used to remove water that has accumulated in a sump pit, typically found in the basement of a building. They are designed to prevent flooding and protect the foundation of the structure. Sump pumps can be either submersible or pedestal-mounted, depending on the application requirements. They are equipped with float switches or level sensors to automatically activate when the water level reaches a predetermined point.

Slurry Pumps

Slurry pumps are designed to handle abrasive and corrosive mixtures of liquids and solids, such as mining slurries, cement, and industrial waste. They feature robust construction materials, such as high-chrome alloys or elastomers, to withstand the harsh operating conditions. Slurry pumps often incorporate features like replaceable wear parts and agitators to ensure efficient operation and minimize downtime.

Fire Pumps

Fire pumps are specialized centrifugal pumps designed to provide high-pressure water flow for fire suppression systems in buildings, industrial facilities, and other structures. They must meet stringent performance and reliability standards set by organizations such as the National Fire Protection Association (NFPA). Fire pumps can be driven by electric motors, diesel engines, or steam turbines, depending on the application and local regulations.

Self-Priming Pumps

Self-priming pumps are designed to automatically remove air from the suction line and pump casing, enabling them to start pumping without the need for manual priming. This is particularly useful in applications where the pump may experience frequent on-off cycles or where the suction source is located above the pump. Self-priming pumps typically employ a built-in priming chamber or an external priming tank to achieve the self-priming function.

Magnetic Drive Pumps

Magnetic drive pumps use a magnetic coupling to transmit power from the motor to the impeller, eliminating the need for a mechanical seal. This design provides a completely sealed and leak-free pumping solution, making them ideal for handling hazardous, toxic, or expensive fluids. Magnetic drive pumps are commonly used in chemical processing, pharmaceutical, and semiconductor industries, where process purity and containment are critical.

Canned Motor Pumps

Canned motor pumps feature a motor that is completely sealed and immersed in the pumped liquid. The motor is cooled and lubricated by the pumped fluid, eliminating the need for external cooling systems or lubrication. Canned motor pumps are commonly used in high-temperature, high-pressure, or ultra-clean applications, such as boiler feed water, reactor coolant, and high-purity chemical processing.

Vertical Turbine Pumps

Vertical turbine pumps are multi-stage centrifugal pumps designed for deep well and high-pressure applications. They consist of multiple impellers stacked vertically on a single shaft, with each stage increasing the pressure of the pumped fluid. Vertical turbine pumps are commonly used in water supply, irrigation, and industrial applications where high head and flow rates are required.

Chopper Pumps

Chopper pumps are designed to handle fluids containing solid particles, such as sewage, industrial waste, and agricultural slurries. They feature a cutting mechanism that shreds solids into smaller pieces before they enter the pump, preventing clogging and ensuring efficient operation. Chopper pumps are often used in municipal and industrial wastewater treatment applications.

Grinder Pumps

Grinder pumps are similar to chopper pumps but are designed for smaller-scale applications, such as residential sewage systems. They incorporate a grinding mechanism that reduces solids into a fine slurry, allowing them to be easily pumped through small-diameter pipes. Grinder pumps are often used in pressure sewer systems and septic tank effluent pumping applications.

Circulator Pumps

Circulator pumps are designed to circulate hot or cold water in closed-loop systems, such as hydronic heating, cooling, and domestic hot water systems. They are typically small, compact, and energy-efficient, with a wide range of flow rates and head pressures to suit various applications. Circulator pumps can be either wet-rotor or dry-rotor designs, depending on the specific requirements of the system.

Sanitary Pumps

Sanitary pumps are designed for use in food, beverage, pharmaceutical, and other hygienic applications where cleanliness and sterility are critical. They feature smooth, polished surfaces and crevice-free designs to prevent the accumulation of bacteria and facilitate easy cleaning. Sanitary pumps are often constructed from stainless steel and comply with strict hygienic standards, such as 3-A Sanitary Standards and FDA regulations.

Chemical Process Pumps

Chemical process pumps are engineered to handle a wide range of corrosive, toxic, and hazardous chemicals in industrial applications. They are constructed from a variety of materials, such as stainless steel, alloy 20, hastelloy, and PVDF, depending on the specific chemical compatibility requirements. Chemical process pumps often incorporate features like sealed bearings, double mechanical seals, and leak detection systems to ensure safe and reliable operation.

Other Classifications

Single Suction Pumps

Single suction pumps have a single inlet on one side of the impeller, where the fluid enters the pump. They are the most common type of centrifugal pump and are used in a wide range of applications, from water supply to industrial processes. Single suction pumps are typically less expensive and more compact than double suction pumps, making them a popular choice for many installations.

Double Suction Pumps

Double suction pumps have an impeller with inlets on both sides, allowing the fluid to enter the pump from two directions. This design balances the hydraulic forces acting on the impeller, reducing shaft deflection and extending bearing life. Double suction pumps are commonly used in high-flow, high-head applications, such as large-scale water supply, power generation, and industrial processes.

Horizontal Split Case Pumps

Horizontal split case pumps have a casing that is split horizontally, allowing easy access to the impeller, shaft, and bearings for maintenance and repair. This design is particularly useful in applications where frequent servicing is required or where downtime must be minimized. Horizontal split case pumps are commonly used in water supply, irrigation, and industrial applications.

Vertical Split Case Pumps

Vertical split case pumps have a casing that is split vertically, with the suction and discharge nozzles located on opposite sides of the casing. This design allows for a more compact installation footprint and is often used in applications where space is limited. Vertical split case pumps are commonly found in HVAC systems, power plants, and industrial processes.

Close Coupled Pumps

Close coupled pumps have the impeller mounted directly on the motor shaft, eliminating the need for a separate coupling and baseplate. This design results in a more compact and cost-effective installation, as well as reduced alignment issues. Close coupled pumps are commonly used in small to medium-sized applications, such as water supply, irrigation, and light industrial processes.

Frame Mounted Pumps

Frame mounted pumps have the pump and motor mounted on a common baseplate, with a coupling connecting the pump and motor shafts. This design allows for greater flexibility in motor selection and facilitates easier maintenance and alignment. Frame mounted pumps are commonly used in larger applications, such as water treatment plants, power generation, and heavy industrial processes.

In conclusion

Understanding the various types of centrifugal pumps is crucial for selecting the right pump for specific applications. Consider factors such as flow rate, pressure, and fluid characteristics when making a decision.

For expert guidance on centrifugal pump selection, consult with a trusted pump supplier or manufacturer.