What’s causing your pump to vibrate excessively? Vibration in pumps can stem from various issues, ranging from misalignment to cavitation.

In this blog post, we’ll explore the common causes of pump vibration and provide you with practical solutions to diagnose and resolve the problem, ensuring your pumping system operates smoothly and efficiently.

Contact Between Components

Signs

Unusual noise or vibration coming from the pump, particularly during startup or shutdown, can indicate contact between internal components. This contact may result in increased wear and damage to the pump.

Causes

Contact between components can be caused by improper assembly, incorrect clearances, or worn-out parts.

Misalignment of the pump and drive system can also lead to contact issues.

Solutions

To resolve contact between components, ensure proper assembly and maintain the recommended clearances between parts.

Replace worn-out components and regularly inspect the pump for signs of wear.

Align the pump and drive system according to the manufacturer’s specifications.

Pump Cavitation

Signs

Cavitation in pumps can be identified by a distinctive crackling or popping noise, similar to the sound of marbles rattling inside the pump. Vibration may also increase, and the pump’s performance may decrease.

Causes

Cavitation occurs when the fluid pressure drops below its vapor pressure, causing vapor bubbles to form. These bubbles collapse when they reach higher-pressure regions, creating shock waves that damage the pump’s internal components.

Cavitation can be caused by insufficient net positive suction head (NPSH), high fluid temperature, or restricted suction lines.

Solutions

To prevent cavitation, ensure that the available NPSH is greater than the required NPSH. Increase the suction pressure by raising the fluid level in the suction tank or reducing the suction line losses. Lower the fluid temperature if possible, and eliminate any restrictions in the suction line.

Pump Flow Pulsation

Signs

Flow pulsation can be detected by fluctuations in the discharge pressure gauge reading or by visible pulsations in the discharge piping. Vibration may also increase due to the unsteady flow.

Causes

Flow pulsation can be caused by improper pump selection, operating the pump too far from its best efficiency point (BEP), or by system design issues such as inadequate pulsation dampeners or pipe supports.

Solutions

To mitigate flow pulsation, select a pump that operates close to its BEP at the desired flow rate.

Install pulsation dampeners to reduce pressure fluctuations and ensure that the piping system is properly supported to minimize vibration.

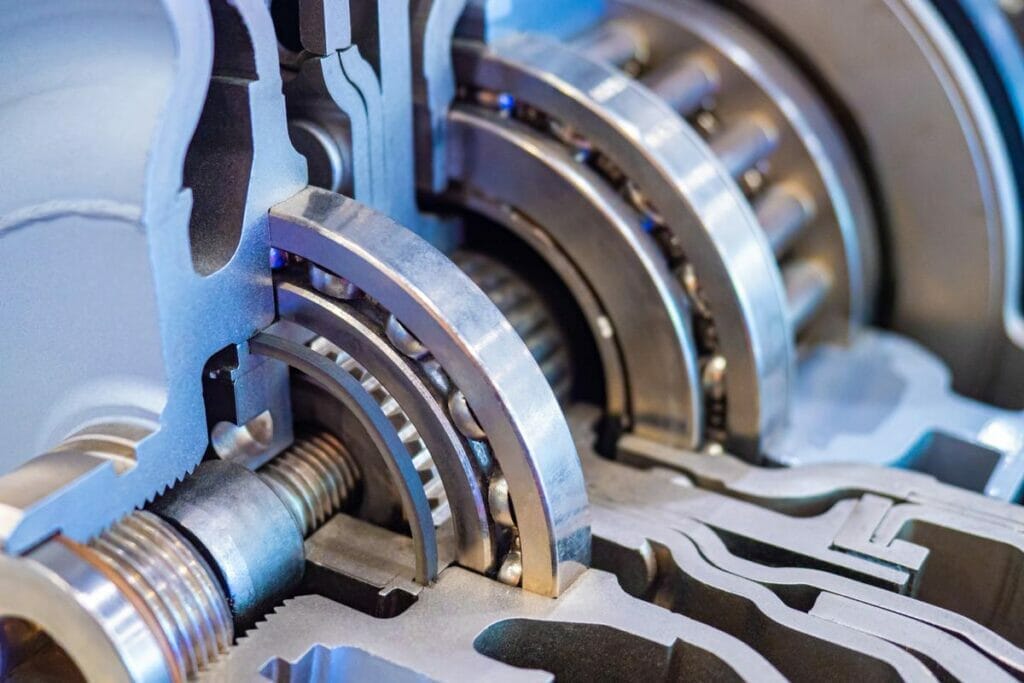

Pump Bearing Issues

Signs

Bearing problems can be identified by increased noise and vibration from the pump, particularly in the bearing housing area. The noise may be described as grinding, rumbling, or squealing. Increased bearing temperature and premature bearing failure are also signs of bearing issues.

Causes

Common causes of pump bearing problems include improper lubrication (either insufficient or excessive), misalignment, overloading, and contamination of the lubricant. Improper installation or selection of bearings can also contribute to bearing failure.

Solutions

To address pump bearing issues, ensure that the bearings are properly lubricated according to the manufacturer’s recommendations. Use the correct type and amount of lubricant, and replace the lubricant at the recommended intervals.

Regularly inspect and replace worn bearings.

Ensure proper alignment of the pump and drive system, and avoid overloading the pump.

Keep the lubricant clean and free from contaminants.

Recirculation

Signs

Recirculation in pumps can be detected by a sudden increase in vibration and noise at specific flow rates. The pump’s performance may also decrease, and the discharge pressure may fluctuate. In severe cases, recirculation can cause cavitation-like damage to the pump’s internal components.

Causes

Recirculation occurs when fluid from the high-pressure side of the pump flows back to the low-pressure side through the clearances between the impeller and the casing. This can be caused by operating the pump at flow rates significantly below its best efficiency point (BEP) or by excessive wear ring clearances.

Solutions

To prevent recirculation, operate the pump close to its BEP whenever possible.

If the pump must operate at low flow rates, consider installing a minimum flow bypass line to ensure sufficient flow through the pump. Maintain the proper clearances between the impeller and wear rings, and replace worn components as necessary.

Aeration

Signs

Aeration in pumps can be identified by a reduction in the pump’s performance, particularly a decrease in discharge pressure and flow rate.

Unusual noises, such as a crackling or gurgling sound, may also be present.

In severe cases, the pump may lose prime or become air-bound.

Causes

Aeration occurs when air or other gases enter the pumping system, either through leaks in the suction line or by vortexing in the suction tank. Dissolved gases in the pumped fluid can also come out of solution due to changes in pressure or temperature.

Solutions

To address aeration issues, ensure that the suction line is properly sealed and free from leaks. Maintain sufficient submergence of the suction pipe in the suction tank to prevent vortexing, and consider installing vortex breakers if necessary.

If dissolved gases are a problem, consider installing a degassing system or using a multistage pump to gradually reduce the pressure and minimize gas separation.

Proper venting of the pump and suction line can also help remove accumulated gases.

Resonance

Signs

Resonance in pumps can be identified by a sudden increase in vibration at specific operating speeds or flow rates. The vibration may be severe and can cause damage to the pump and surrounding equipment. In some cases, the pump may exhibit excessive movement or deflection.

Causes

Resonance occurs when the natural frequency of the pump or its components coincides with the frequency of an excitation force, such as the rotating speed or the vane passing frequency. This can be caused by improper pump selection, poor system design, or changes in the operating conditions.

Solutions

To prevent resonance, ensure that the pump and its components are designed to operate well away from their natural frequencies. This may involve changing the pump type, modifying the pump geometry, or adjusting the operating speed.

In some cases, adding mass or stiffness to the pump or its supporting structure can shift the natural frequencies away from the excitation frequencies.

Properly isolating the pump from the piping system can also help reduce the transmission of vibration.

Improper Installation

Signs

Improper installation can lead to a variety of problems, including increased vibration, noise, and premature component failure. The pump may also exhibit poor performance, such as reduced flow rates or discharge pressures. Misalignment between the pump and driver can cause excessive wear on the bearings and couplings.

Causes

Improper installation can be caused by a lack of proper planning, inadequate foundation design, or poor workmanship. Misalignment, incorrect piping connections, and improper baseplate grouting are common examples of installation issues.

Solutions

To avoid improper installation, follow the manufacturer’s installation guidelines and industry best practices. Ensure that the foundation is properly designed and constructed to provide a stable and level surface for the pump.

Use laser alignment tools to precisely align the pump and driver.

Properly support and anchor the piping to minimize strain on the pump nozzles.

Grout the baseplate to ensure full contact between the pump and foundation, and allow adequate curing time before starting the pump.

Worn Components

Signs

Worn pump components can cause increased vibration, noise, and a decrease in pump performance. Specific signs may include increased bearing temperature, leaking seals, and visible wear on the impeller, wear rings, or other internal parts.

Causes

Pump components can wear out due to normal use over time, but premature wear can be caused by factors such as abrasive particles in the pumped fluid, cavitation, or improper maintenance. Operating the pump outside its recommended range can also accelerate wear.

Solutions

To address worn components, establish a regular maintenance schedule that includes inspecting and replacing wear parts as needed.

If abrasive particles are present, consider installing a strainer or filter to remove them from the fluid.

Properly maintain the pump’s lubrication system and keep the lubricant clean to extend the life of the bearings and other components.

Looseness

Signs

Looseness in pumps can be detected by a rattling or knocking noise, particularly during startup or shutdown. The vibration may also increase, and the amplitude of the vibration may vary with the pump speed. Loose components may cause excessive movement or deflection of the pump or its attached piping.

Causes

Looseness can be caused by improper assembly, inadequate tightening of bolts, or deterioration of the pump’s foundation or baseplate. Thermal expansion and contraction of the pump and piping can also cause components to loosen over time. Excessive vibration from other sources, such as cavitation or misalignment, can contribute to looseness.

Solutions

To address looseness, ensure that all bolts and fasteners are properly tightened to the manufacturer’s recommended torque values. Use appropriate locking devices, such as lock washers or locking adhesives, to prevent bolts from loosening.

Regularly inspect the pump and its components for signs of wear or damage, and replace worn parts as necessary.

Ensure that the pump’s foundation and baseplate are in good condition and properly grout the baseplate to provide a stable support for the pump.

If thermal expansion is a problem, consider using flexible couplings or expansion joints to accommodate the movement.

Hydraulic Excitation Forces

Signs

Hydraulic excitation forces can cause excessive vibration and noise in pumps, particularly at specific flow rates or operating speeds. The vibration may be more severe in certain directions, such as axially or radially. In some cases, the pump may exhibit a “whipping” motion or oscillate at a specific frequency.

Causes

Hydraulic excitation forces are caused by the interaction between the pumped fluid and the pump’s internal components, such as the impeller and volute. These forces can be generated by factors such as uneven pressure distribution, flow separation, or vortex shedding. Improper pump design, operating the pump at off-design conditions, or wear of the pump’s components can contribute to the development of hydraulic excitation forces.

Solutions

To mitigate hydraulic excitation forces, ensure that the pump is properly designed for the intended operating conditions. This may involve using computational fluid dynamics (CFD) analysis to optimize the pump’s internal geometry and minimize flow disturbances.

Operate the pump within its recommended range of flow rates and speeds to avoid off-design conditions that can generate excessive forces.

Regularly inspect and maintain the pump’s components, such as the impeller and volute, to ensure they are in good condition and not contributing to the development of hydraulic excitation forces.

In some cases, modifying the pump’s internal geometry or installing flow-straightening devices can help reduce the excitation forces.

FAQs

What is the acceptable vibration level for a pump

The acceptable vibration level for a pump depends on its size and operating speed. Generally, vibration velocity should be below 0.3 in/sec. Anything higher may indicate issues like imbalance, misalignment, or bearing wear that require attention.

How does fluid viscosity affect pump vibration

Pumping fluids with higher viscosity than the pump is designed for can cause increased load on the pump, leading to vibration and reduced efficiency.

Can pipe strain cause vibration in pumps

Yes, pipe strain caused by misaligned or improperly supported piping can transfer stress to the pump, resulting in vibration and potential damage to the pump components.

Conclusion

In conclusion, vibrations in pumps can be caused by various factors such as cavitation, imbalance, misalignment, and bearing issues. Identifying and addressing the root cause is crucial for maintaining pump performance and longevity.

For expert assistance in diagnosing and resolving pump vibration problems, contact a trusted pump specialist today.