What measurements do you need to take?

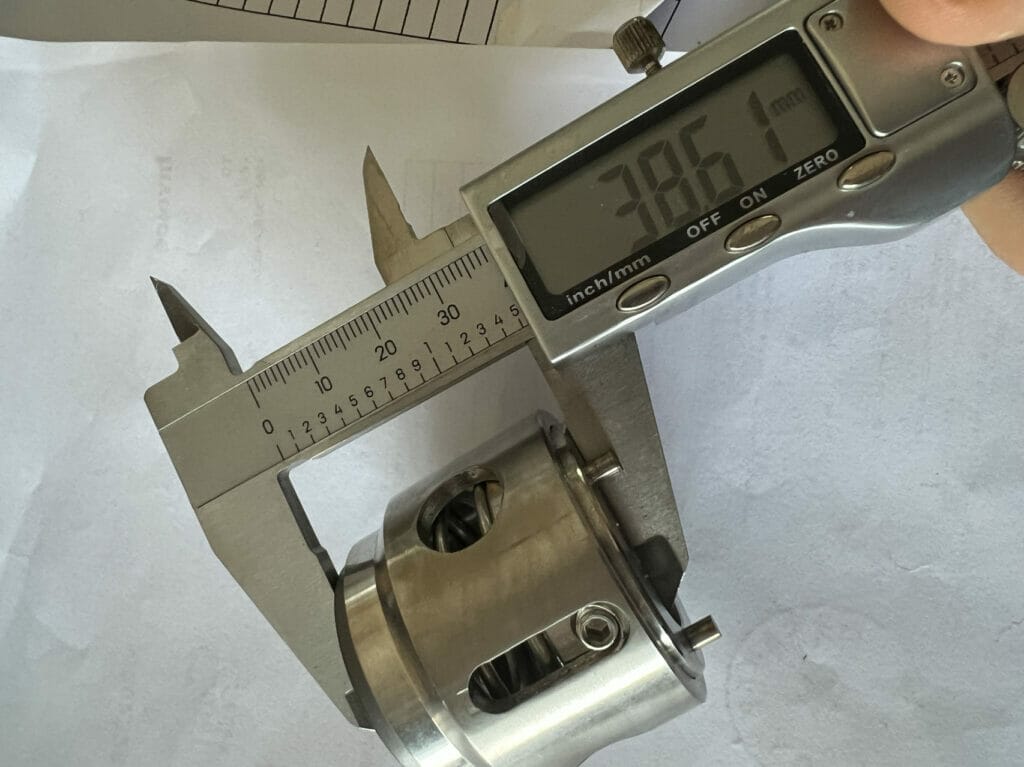

Before measuring your mechanical seal, you should be aware of the critical components. The stationary face, rotating face, and working length are all essential to proper sizing. You’ll require a dial caliper to take accurate measurements.

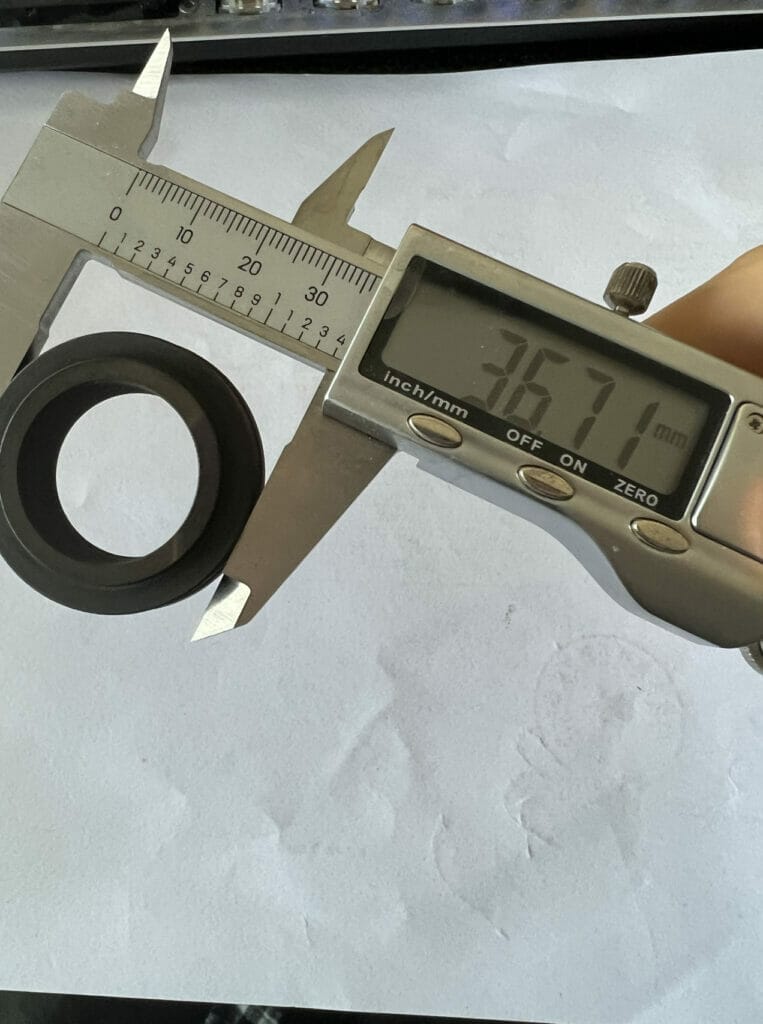

Measure the stationary face

First, remove the mechanical seal from the pump. Measure the inside diameter (I.D.) of the stationary face and the outside diameter (O.D.) of the stationary face using your micrometer. Record these measurements, as these are necessary when cross-referencing for a replacement seal.

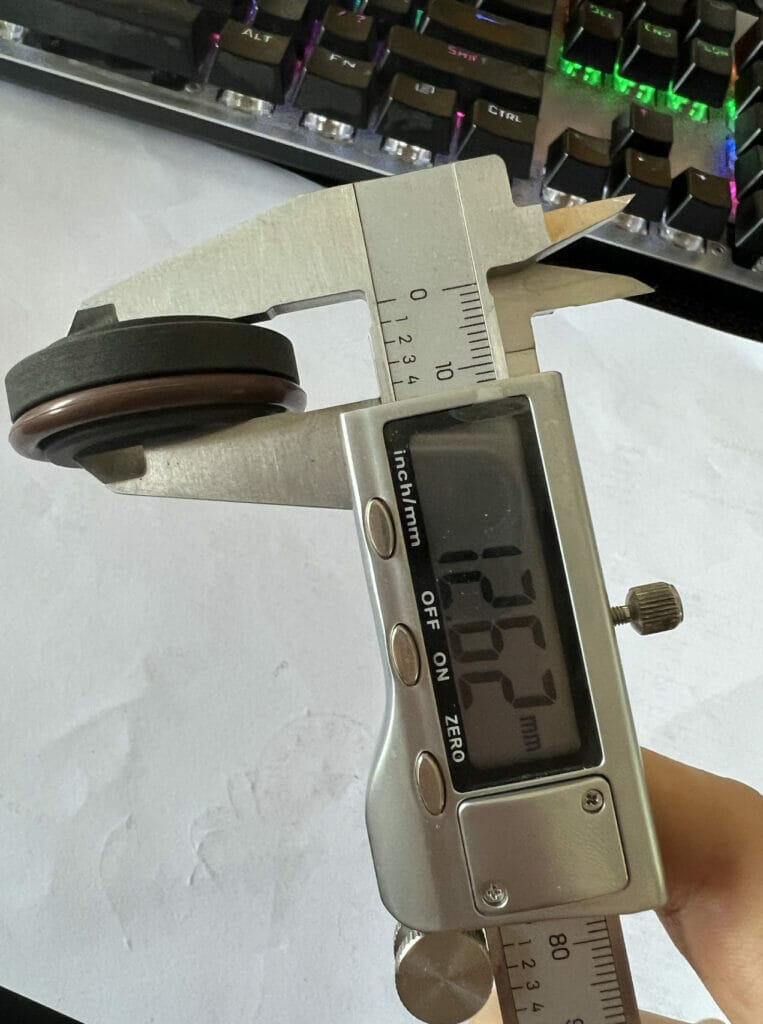

Sometimes you need to measure the height of the stationary face.

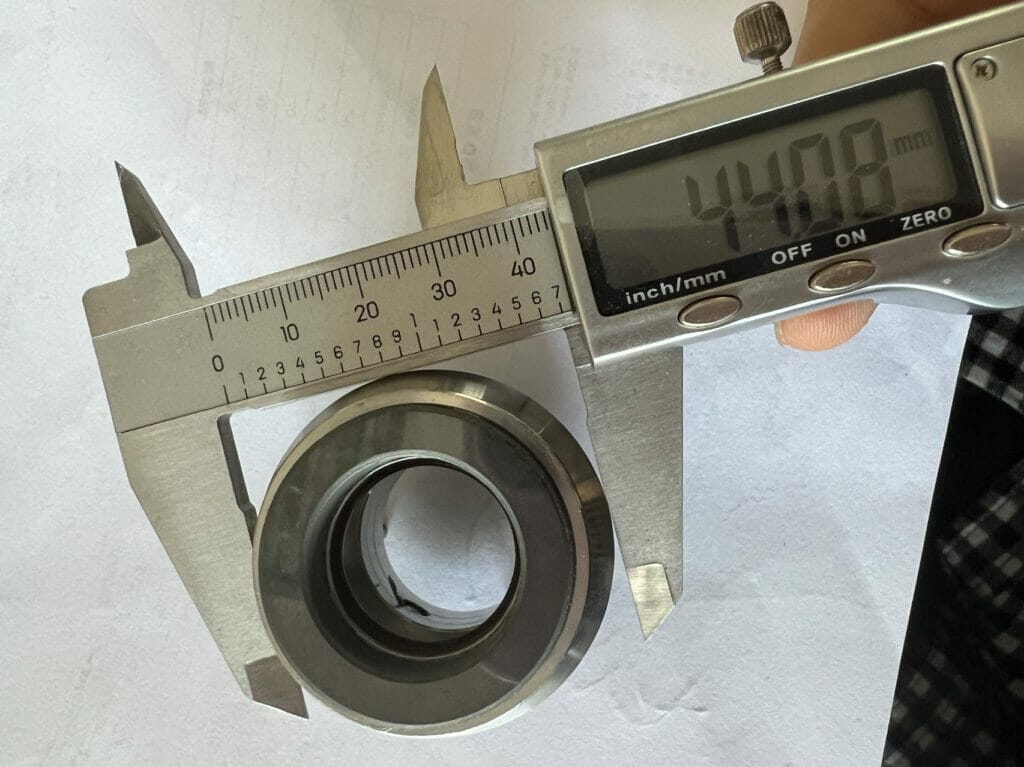

Measure the rotating face

Measure the rotating face outside diameter (O.D.) and the inside diameter (I.D.). Record these measurements for cross-referencing.

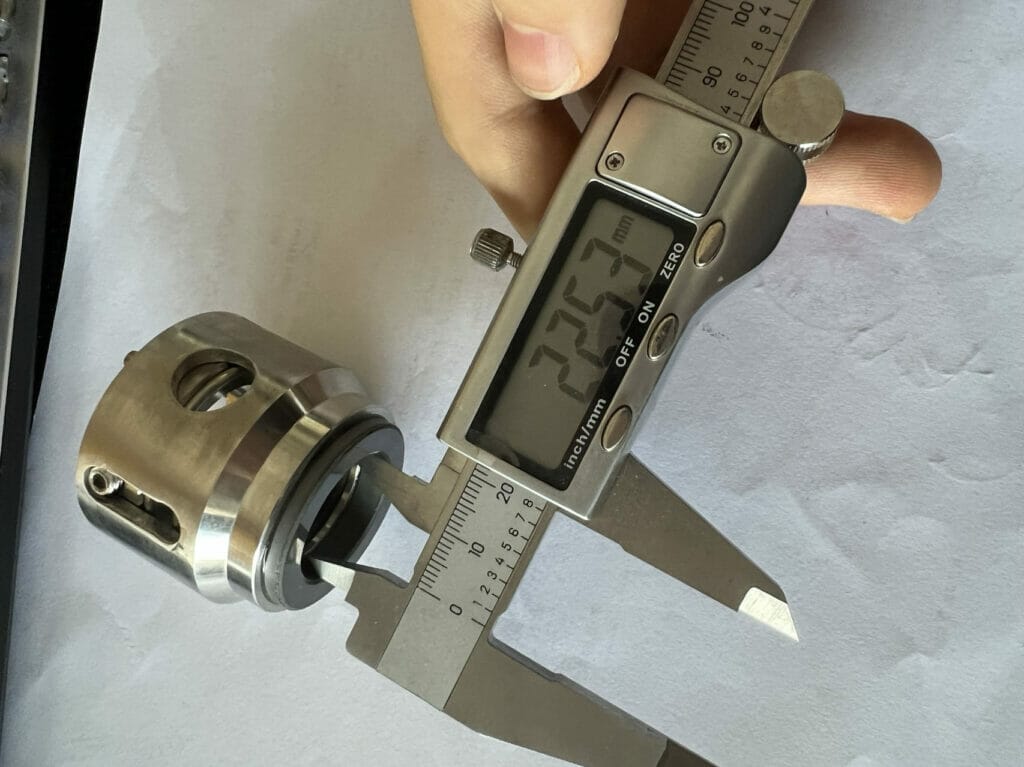

Measure the working length

The seal working length is the height of the rotating face. It is usually the length of the spring or bellows in its natural state.

This measurement is critical, and choosing the right working length ensures the proper amount of compression.

FAQs

What tools do I need to measure a mechanical seal?

You will need a caliper or a seal measuring kit to accurately measure the dimensions of a mechanical seal.

Can I measure a worn or damaged mechanical seal?

Yes, but be cautious as worn or damaged seals may not provide accurate measurements. It’s best to measure a new, unused seal.

How do I know if I’ve measured the seal correctly?

Double-check your measurements and compare them with the manufacturer’s specifications or a seal cross-reference chart.

What other factors should I consider when selecting a mechanical seal?

In addition to size, consider the seal material, type, and operating conditions (e.g., temperature, pressure, and fluid compatibility) to ensure proper performance.

Do I need to measure the shaft diameter?

Usually you don’t need to measure the diameter of the shaft, because the above data is enough for normal cases.

Sometimes you need to customize a very precise mechanical seal, then you’d better measure the diameter of the shaft.

Conclusion

Measuring mechanical seal size is straightforward with the right tools and knowledge. Following these steps will ensure the correct seal is ordered for optimal performance and lifespan.

Still have questions? Contact our knowledgeable support team for personalized assistance in finding the ideal mechanical seal for your application.