Have you ever wondered how to ensure your mechanical seals are functioning properly? A leak test is a crucial procedure that can help you identify and prevent potential issues.

In this blog post, we’ll walk you through a step-by-step guide on conducting a mechanical seal leak test, empowering you to maintain your equipment’s integrity and optimize its performance.

What Is a Mechanical Seal Leak Test

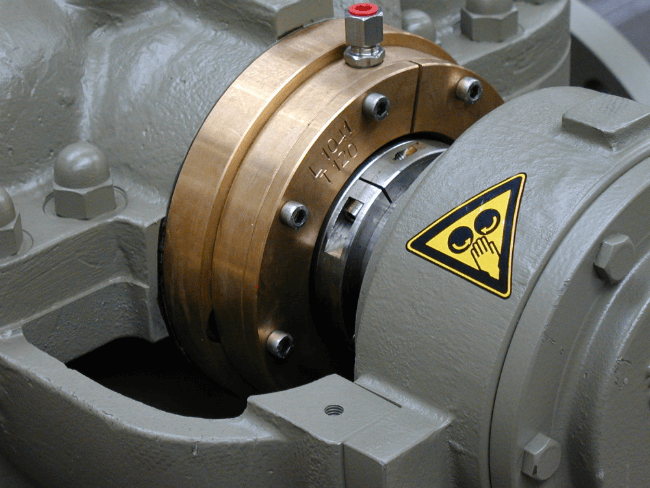

A mechanical seal leak test is a procedure to check for leaks in mechanical seals, which are used to prevent fluid leakage around rotating shafts in pumps, compressors, and other equipment.

Step by Step for Mechanical Seal Leak Test

Preparation

Before beginning the mechanical seal leak test, ensure that all necessary equipment and materials are available. This includes:

- The mechanical seal to be tested

- A test rig or suitable testing apparatus

- Pressure gauges and sensors

- Leak detection fluid (e.g., dye or fluorescent liquid)

- Cleaning supplies and tools

Assembly

Carefully assemble the mechanical seal into the test rig according to the manufacturer’s instructions. Make sure that all components are properly aligned and secured. Double-check that the seal faces are clean and free from any debris or damage.

Pressurization

Once the mechanical seal is assembled, gradually pressurize the test rig to the specified testing pressure. Monitor the pressure gauges to ensure that the pressure remains stable and within the desired range. Allow the system to stabilize for a predetermined period before proceeding to the next step.

Leak Detection

Apply the leak detection fluid to the atmospheric side of the mechanical seal. Observe the seal faces closely for any signs of leakage. If a leak is detected, it will be indicated by the presence of the detection fluid on the process side of the seal. Record the location and severity of any leaks.

Monitoring

Continue monitoring the mechanical seal for the duration of the test, which is typically specified by industry standards or customer requirements. Regularly check the pressure gauges and leak detection points to ensure that the seal remains stable and leak-free throughout the test.

Documentation

Throughout the leak test procedure, maintain accurate records of all observations, measurements, and any adjustments made. This documentation should include the test duration, pressure readings, leak detection results, and any other relevant information.

Completion

Upon completion of the leak test, carefully depressurize the test rig and disassemble the mechanical seal. Clean all components thoroughly and inspect the seal faces for any signs of wear or damage. If the seal has passed the leak test, it can be prepared for installation or storage as required.

Types of Mechanical Seal Leak Test Methods

Pressure Decay Method

In this method, the mechanical seal is subjected to a specific pressure, and the pressure decay over time is monitored. A rapid pressure drop indicates the presence of leaks in the seal.

Bubble Test Method

The mechanical seal is submerged in a transparent fluid, and air pressure is applied to the seal cavity. The formation of bubbles in the fluid indicates the existence of leaks.

Helium Leak Detection

This highly sensitive method involves using helium gas as a tracer. The mechanical seal is placed in a vacuum chamber, and helium is introduced into the seal cavity. A helium leak detector is used to identify any leaks in the seal.

FAQs

How often should a mechanical seal leak test be performed?

The frequency of mechanical seal leak tests depends on the equipment, operating conditions, and manufacturer’s recommendations. Generally, tests should be conducted during routine maintenance or when a leak is suspected.

Can a mechanical seal leak test be performed while the equipment is running?

No, a mechanical seal leak test should be performed when the equipment is shut down and properly isolated to ensure safety and accurate test results.

In conclusion

Following a proper mechanical seal leak test procedure is crucial for ensuring the reliability and safety of your equipment. By implementing these steps, you can prevent costly failures and downtime.

Don’t wait – start optimizing your mechanical seal performance today and reap the benefits for your business.