Have you ever wondered what a mechanical seal sleeve is and why it’s important? In this blog post, we’ll explore the crucial role that seal sleeves play in preventing leaks and ensuring the smooth operation of rotating equipment. By the end, you’ll have a clear understanding of how these simple yet essential components work to keep your machinery running efficiently.

What is a Mechanical Seal Sleeve

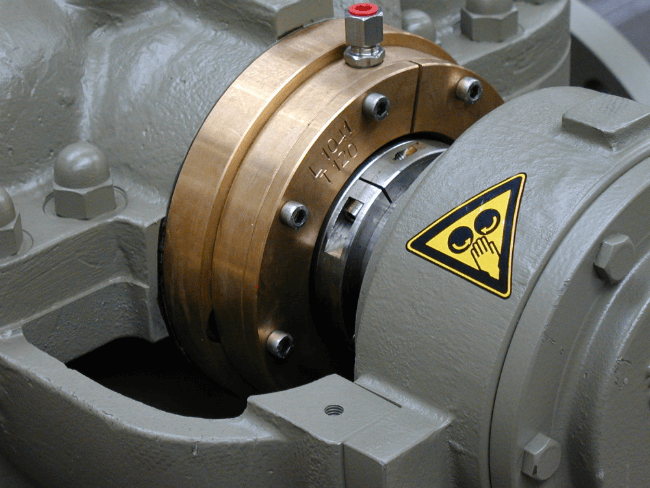

A mechanical seal sleeve is a cylindrical component that plays a crucial role in the proper functioning of mechanical seals. It is designed to fit over the shaft or spindle of a rotating piece of equipment, such as a pump, mixer, or compressor.

The primary purpose of a mechanical seal sleeve is to provide a smooth, wear-resistant, and corrosion-resistant surface for the mechanical seal to ride on, ensuring optimal sealing performance and prolonging the life of the seal.

How does a mechanical seal sleeve work?

The mechanical seal rides on the surface of the sleeve, creating a barrier between the sealed fluid and the atmosphere. The sleeve rotates with the shaft, providing a continuous sealing surface.

Common Materials for Mechanical Seal Sleeves

Mechanical seal sleeves are typically manufactured from high-quality, durable materials that can withstand the harsh operating conditions found in various industrial applications. Some of the most common materials used for seal sleeves include:

- Stainless steel: Known for its excellent corrosion resistance and strength, stainless steel is a popular choice for seal sleeves in many industries. Different grades of stainless steel, such as 304, 316, and 17-4 PH, offer varying levels of durability and resistance to specific environments.

- Hastelloy: This nickel-based superalloy provides exceptional resistance to corrosion, oxidation, and high temperatures. Hastelloy is often used in seal sleeves for applications involving highly corrosive or acidic media.

- Titanium: With its high strength-to-weight ratio and excellent corrosion resistance, titanium is an ideal material for seal sleeves in industries such as chemical processing, oil and gas, and marine applications.

Types of Mechanical Seal Sleeves

Standard Sleeves

Standard sleeves are the most basic type, typically made from stainless steel or other corrosion-resistant materials. They are designed to fit over the shaft and provide a smooth, wear-resistant surface for the mechanical seal to run against.

Coated Sleeves

Coated sleeves feature a specialized coating applied to the surface of the sleeve to enhance its properties. Common coatings include chrome oxide, tungsten carbide, and silicon carbide. These coatings improve the sleeve’s hardness, wear resistance, and corrosion resistance, making them suitable for more demanding applications.

Split Sleeves

Split sleeves consist of two halves that can be assembled around the shaft without the need for complete disassembly of the equipment. This design allows for easier installation and maintenance, particularly in situations where the shaft cannot be easily removed.

Cartridge Sleeves

Cartridge sleeves are pre-assembled units that include the sleeve, gland plate, and mechanical seal components. They offer the advantage of simplified installation and ensuring proper alignment of the seal components. Cartridge sleeves are commonly used in applications where quick and easy seal replacement is required.

Lightweight Sleeves

Lightweight sleeves are designed to reduce the overall weight of the sealing assembly. They are typically made from materials such as aluminum, titanium, or composite materials. Lightweight sleeves are particularly beneficial in applications where weight reduction is crucial, such as in aerospace and high-speed rotating equipment.

FAQs

Can a damaged mechanical seal sleeve be repaired?

In most cases, a damaged mechanical seal sleeve cannot be repaired and must be replaced to ensure proper sealing and prevent shaft damage.

How do I know if my mechanical seal sleeve needs to be replaced?

Signs that a mechanical seal sleeve needs replacement include excessive wear, scoring, or damage to the sleeve surface, as well as leakage from the mechanical seal.

Can I replace a mechanical seal sleeve without replacing the entire seal?

Yes, in many cases, the mechanical seal sleeve can be replaced independently of the seal itself, as long as the seal is in good condition and compatible with the new sleeve.

Are mechanical seal sleeves universal or specific to each seal?

Mechanical seal sleeves are typically designed to work with specific seal models and shaft sizes. It is essential to select a sleeve that is compatible with your existing seal and equipment.

What is the difference between a mechanical seal sleeve and a shaft sleeve?

A mechanical seal sleeve is specifically designed to work with a mechanical seal, providing a sealing surface, while a shaft sleeve is a more general component that protects the shaft from wear and damage.

In conclusion

Mechanical seal sleeve plays a crucial role in protecting and extending the life of mechanical seals. By understanding its function and proper installation, you can ensure optimal performance and reliability of your sealing system. For more information or assistance, contact a trusted mechanical seal supplier today.